Leading Tips for Effective Commercial Refrigeration Repair in Toronto

Leading Tips for Effective Commercial Refrigeration Repair in Toronto

Blog Article

The Ultimate Guide to Commercial Refrigeration Repair: Usual concerns and crucial actions Described

Typical Commercial Refrigeration Concerns

When running commercial refrigeration devices, services may encounter several usual problems that can affect the effectiveness and functionality of the devices. One prevalent trouble is improper temperature level regulation. Rising and fall temperatures within the refrigeration device can cause food putridity, raised energy intake, and jeopardized quality and safety and security standards. This concern typically originates from a malfunctioning thermostat, incorrect door seals, or inadequate insulation.

One more usual concern is refrigerant leaks. Leaks can result from damage, poor installation, or making issues. Low refrigerant levels not only impede the device's air conditioning ability but can also result in compressor failing if left unaddressed.

Additionally, ice buildup on evaporator coils is a frequent worry. Ice build-up limits air flow, triggering the system to function more challenging and consume even more energy. Routine cleaning and maintenance of the coils can help stop this concern.

Vital Tools for Repairing Refrigeration Units

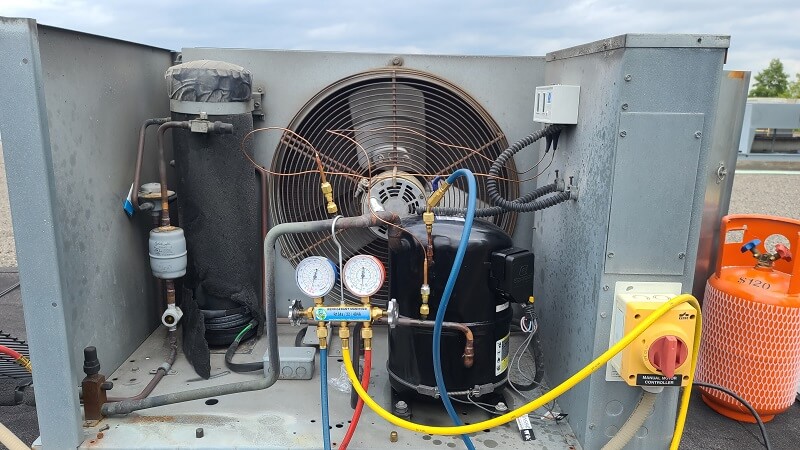

Utilizing the ideal devices is essential for properly repairing commercial refrigeration systems to guarantee optimum performance and long life. Among the basic devices called for are manifold assesses for inspecting cooling agent pressures, refrigeration wrenches for tightening up or loosening installations, a multimeter for screening electrical parts, and leak discovery tools such as digital leakage detectors or ultraviolet dye packages.

In the realm of specialized devices, tube cutters and flaring devices are essential for collaborating with copper tubes, while a healing maker is needed for securely eliminating refrigerants. Furthermore, a temperature gun can be useful for rapidly identifying temperature level differentials within the device. Buying high-grade devices not only enhances performance throughout fixings yet additionally adds to the accuracy and integrity of the maintenance work performed on business refrigeration devices.

Step-by-Step Troubleshooting Overview

The following step is to evaluate the temperature controls and setups to guarantee they are working properly. This includes checking the thermostat, thaw timer, and various other control systems to validate that they are managing the temperature level as meant. If any discrepancies are located, changes or substitutes may be required. commercial refrigeration repair.

Subsequently, the professional must examine the condenser and evaporator coils for dust or debris accumulation, which can hamper correct cooling. Cleaning these parts can often solve issues with temperature level guideline and efficiency.

Preventative Maintenance Techniques

Executing regular preventative upkeep steps is essential for guaranteeing the long life and optimum efficiency of industrial refrigeration systems. By adhering to a proactive upkeep timetable, services can lessen the danger of expensive breakdowns, prevent downtime, and prolong the lifespan why not check here of their refrigeration tools.

One crucial preventative maintenance method is routine cleaning of condenser coils. In time, these coils can accumulate dirt, particles, and dust, which can impede warmth transfer and decrease the system's effectiveness. By cleaning the coils occasionally, companies can ensure that the refrigeration system operates at peak efficiency.

Additionally, inspecting and changing worn gaskets on doors is one more critical maintenance job. Damaged gaskets can cause air leakages, causing the refrigeration system to work harder to keep the preferred temperature level. By replacing defective gaskets without delay, businesses can enhance power performance and extend the life of the equipment.

Including these preventative maintenance methods into an extensive upkeep strategy can help organizations optimize the performance and dependability of their business refrigeration systems.

Professional Repair Work Vs. DIY: Pros and Disadvantages

Involving a professional repair service for industrial refrigeration systems uses distinctive benefits over trying do it yourself repairs. Commercial refrigeration systems are complicated systems that call for specialized expertise and abilities to detect and fix properly. Specialists have the training and experience to recognize concerns accurately, leading to quicker and more precise repairs. They also have access to advanced tools and devices that may not be conveniently offered to the average individual.

In addition, specialist repair service services typically offer service warranties on their job, providing you satisfaction knowing that the work is ensured. Attempting to fix an industrial refrigeration system yourself can cause additional damages otherwise done correctly, possibly leading to more pricey repair services down the line. Furthermore, DIY repair work might nullify any existing service warranties on the equipment, leaving you only accountable for any future concerns that may emerge. While do it yourself repairs might seem economical originally, the lasting benefits of expert repair work services exceed the unpredictabilities and risks connected with trying repair services on your own.

Final Thought

Finally, understanding typical industrial refrigeration concerns, having the vital devices for fixing, following a step-by-step troubleshooting overview, and applying preventative upkeep techniques are key elements of preserving and fixing business refrigeration devices. While expert repair services may offer know-how and performance, do it yourself fixings can additionally Full Report be an affordable option for those with the required skills and understanding. Eventually, routine maintenance and prompt repair work are vital for making sure the appropriate performance of industrial refrigeration systems.

Comprehending the vital steps read what he said for commercial refrigeration repair work and being able to identify common issues are crucial skills for any kind of organization proprietor or maintenance workers. In this extensive guide, we will explore the basic actions and typical issues in commercial refrigeration repair, equipping you with the expertise needed to deal with these challenges efficiently.

Engaging a specialist fixing service for commercial refrigeration systems offers distinctive benefits over trying DIY repair work. Attempting to fix an industrial refrigeration system yourself can lead to more damage if not done appropriately, possibly resulting in more pricey repair work down the line.In verdict, comprehending common industrial refrigeration issues, having the crucial tools for repair, adhering to a step-by-step troubleshooting overview, and carrying out preventative maintenance strategies are essential parts of maintaining and fixing commercial refrigeration systems.

Report this page